Wheel hub motor technology is also called in-wheel motor technology. Wheel hub motor is the motor embedded in the wheel, the stator is fixed on the tire, the rotor is fixed on the axle, and the stator and rotor move relative to each other when power is applied. The electronic phase converter (switch circuit) controls the energization sequence and time of the stator windings according to the position sensor signal, generates a rotating magnetic field, and drives the rotor to rotate. Its biggest feature is that the power, transmission and braking devices are integrated into the wheel hub, thus greatly simplifying the mechanical part of the electric vehicle.

The wheel hub motor is simple in structure, sturdy and durable, low in cost, and reliable in operation. A large number of transmission components can be omitted, making the vehicle structure simpler and realizing a variety of complex driving methods. So what are the characteristics of the wheel hub motor?

1. The wheel hub motor has simple structure, sturdiness and durability, low cost, reliable operation, small torque ripple, low noise, no position sensor, and high speed limit; the disadvantage is that the drive circuit is complex and the cost is high. Compared with permanent magnet motors, The efficiency and power density of asynchronous motors are low;

2. The wheel hub motor can adopt cylindrical radial magnetic field structure or disc axial magnetic field structure, with high power density and efficiency, and wide speed range, and its development prospects are very broad;

3. The wheel hub motor has the characteristics of simple structure, low manufacturing cost, and good speed/torque characteristics. The wheel hub motor is not only suitable for electric bicycles, but also suitable for electric vehicle driving; the disadvantage is that the design and the controlling are very difficult and precise, and the operation noise is large.

Hub motor types are mainly divided into five types, that is, brush and brushless motor; with sensor and with sensor; with and without gears; with and without clutch mechanism; high speed and low speed.

Due to the low efficiency, brush motors for vehicles have been phased out. Brushless wheel hub motor is still in use. Here, we present the key differences between e-bike brushless motors and brushed motors:

| Feature | Brushless Motor | Brushed Motor |

| Service Life | Approximately 20,000 hours (7-10 years) | Approximately 5,000 hours (2-3 years) |

| Running Speed | High speed (90-95 m/s) | Lower speed than brushless motors |

| Energy Efficiency | Power consumption is 1/3 of brushed motors | Higher power consumption |

| Maintenance | Low maintenance, less prone to damage | Higher maintenance due to brush wear |

| Weight | Generally lighter | Generally heavier |

| Torque | Higher torque at low speeds | Lower torque at low speeds |

| Control Complexity | More complex control circuit | Simpler control system |

| Climbing Ability | Strong climbing ability | Great power but prone to wear |

| Cost of Components | Higher precision required, more expensive | Lower cost, but requires frequent brush replacement |

| Riding Experience | Smoother and safer ride | Can be noisier and less smooth |

| Applications | Common in high-performance e-bikes | Often used in budget or entry-level e-bikes |

As one of the trusted hub motor manufacturers, Shengyi provides premium brushless ebike motor.

Shengyi brushless motors, specifically the DGW07-R16 and DGW25R models, stand out for their efficiency, power, and versatility. Each offers a reliable and energy-efficient solution for your electric bike needs.

High Efficiency: The direct drive hub motor boasts an efficiency of ≥80%, ensuring that a significant portion of the battery power is converted into usable energy, leading to longer rides on a single charge.

Robust Construction:Both motors feature a waterproof classification of IPX5, providing protection against water splashes, making them suitable for various weather conditions.

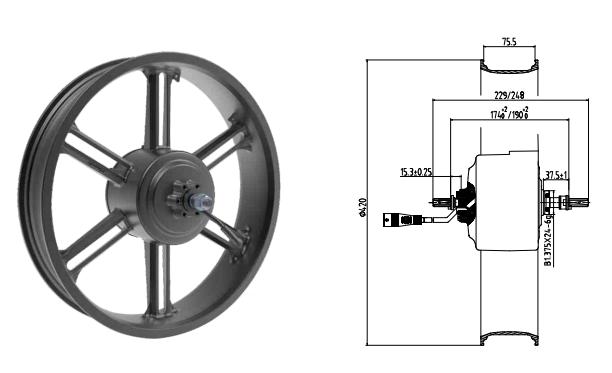

Lightweight Design: The motor r16 weighs 4.0 kg, and the DGW25R weighs 4.9 kg. The lightweight design contributes to the overall performance of the e-bike, enhancing speed and maneuverability.

Customizable Features:Both models come with options for Hall sensors (with or without), and inside speed sensors that can be configured from 1 to 6. This allows for tailored performance based on rider preference.

Easy Installation: The installation dimensions are manageable, with the DGW07-R16 measuring 145 mm and the DGW25R ranging from 175 mm to 190 mm, facilitating straightforward integration into various e-bike frames.

Whether for commuting or off-road adventures, Shengyi ebike brushless motor provide reliable performance and enhanced riding experiences.

Some electric bicycles must be stepped on to drive because there are no sensors inside. It directly measures the back electromotive force of the motor and knows the position of the rotor to perform commutation. To know the relative position of the rotor and stator before starting, a sensor must be used.

In order to prevent the magnetic steel from demagnetizing and reduce the starting current of the motor, a reduction gear must be used to improve the starting efficiency. After the magnetic steel material is improved, gears are not necessary.

Variable reluctance wheel hub motors, electric bicycles using wheel hub motors will have electromagnetic resistance when riding without electricity, and the use of a clutch mechanism can reduce the electromagnetic resistance. A clutch mechanism can also be used to adjust the gear speed ratio. Magnetic manual gear clutch high-speed brushless hub motor, using motor magnetic reset to achieve manual gear meshing.

The magnetic manual gear clutch high-speed brushless hub motor is light in weight, and the low-speed brushless hub motor has a simple structure, low noise and high power.